THE LOGITEC MIXING LINES ML15, ML30 AND ML60 (20, 40 and 80 cu yd) : compact, mobile systems with a modular construction for upgrading basic substrates and raw materials.

How does the Logitec Mixing Line work?

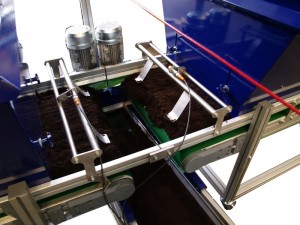

The Logitec Mixing Line is a compact, mobile system that can be used to upgrade a basic substrate or raw materials to any composition desired. The installation can be supplied by one or multiple Big-Bale dosing bunkers. Desired amounts of a variety of fertilizers, as well as Osmocote, perlite and lime, among others, are added to a layer of basic substrate on a conveyor belt. The machine enables the user to compose their own “recipes”, and to possibly develop these. The “recipes” can be saved in the machine’s memory, so that they can easily be used again. The quantities and composition of a “recipe” are easily adjusted. You can inspect your product, and make changes if necessary. The basic substrate and aggregates are mixed (rapidly or vigorously as desired) in a specially designed horizontal mixing drum. Optionally, after the mixing process, an amount of water can be added to the finished product. The Logitec Mixing Line can also directly supply a potting machine, so that the product can be processed immediately.

Characteristics of the Logitec Mixing Line:

- Modular composition that can be customized or expanded if required;

- Easy to transport in separate components;

- Design one’s own recipes with fertilizers of choice;

- The machine is very easy to calibrate;

- Recipes can be stored in the machine’s memory in the fully automatic version;

- Works in conjunction with almost every other brand and type of potting machine.

The Logitec Mixing Lines can process the following products, among others:

- White peat

- Black peat

- Compost

- Sand

- Clay

- Perlite

- Vermiculite

- Osmocote

- Artificial fertilizers

- Lime

- Organic fertilizers

Electricity:

- 400 volts / 3-phase + ground / 50Hz.

- Other voltages upon request.

Capacity:

- ML15: up to 15 m³ per hour

- ML30: up to 30 m³ per hour

- ML60: up to 60 m³ per hour

- Other capacities upon request

Models:

- Manual version requiring manual adjustment of the speed of the vibrational dosing units and the raw-material belts. The mixing option (normal or intensive) is also set by hand.

- Fully automatic version, in which all the parameters are controlled centrally by a computer with touch screen. This model also allows recipes and settings to be saved.

Options:

- Supply bunkers for the basic substrate (peat, bark, perlite, etc.) sized 0.8 m³, 1.2 m³, 1.5 m³, 3m³, 7.5 m³, or as large as 10 m³, with removal belt and support frame.

- Vibrational dosing units sized 9 L, 25 L, 50 L, 200 L or 500 L for careful measurement of the aggregates used.

- Water provision system

Made in Netherlands LOGITEC PLUS.